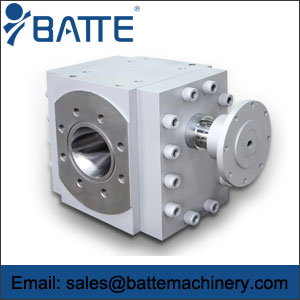

polypropylene melt pump

Available in a wide variety of capacities and models, the melt pump provides accurate, consistent and reliable fluid metering for virtually all polymers used in the plastics industry including: Polyester, Polypropylene, Nylon, Acrylic, Cellulose, Spandex, and many specialty fibers.

The benefits of using a polypropylene melt pump

1, to improve the dimensional stability - polypropylene melt pump effectively isolate the die and the pressure fluctuations from the upstream, the extrusion products to minimize dimensional tolerances.

2, control the melt quality - polypropylene melt pump to adjust the extruder back pressure to reduce the residence time, stable plastic refining

Use, and reduce the melting temperature.

3, increase production - polypropylene melt pump reduces the pressure on the screw requirements, the screw can be extruded at high speed and efficiency, regardless of the size of the pressure required to establish, have provided very high efficiency.

4, to reduce the use of raw materials - based on the final product size changes in small, reduce waste and reduce scrap rates.

5, to eliminate fluctuations and screw impact - polypropylene melt pump effectively solve the pressure due to melt density or extruder pressure fluctuations.

6, enhanced the flexibility of the extruder - allow to change the processing conditions, such as: higher back to the amount of material, temperature and pressure.

7, reasonable operation and operation - polypropylene melt pump pressure closed-loop control, PLC or smart meter.

8, low operating costs - to provide more accurate measurement of delivery, to avoid waste of raw materials.

9, to extend the life of the extruder - polypropylene melt pump to reduce the extruder extrusion pressure, reducing the work of the extruder strength, can greatly delay the screw and barrel wear and tear, extending the extruder life.

|

Type

|

CC/Rev

|

Capacity (L/H)

|

Heating power (kw)

|

Driven system (km)

|

|

ZB-0.2

|

0.2

|

0.1-0.6

|

0.5

|

0.37

|

|

ZB-1

|

1

|

0.5-3

|

1

|

0.5

|

|

ZB-2

|

2

|

1-6

|

1

|

0.75

|

|

ZB-5

|

5

|

2.5-15

|

1

|

1.1

|

|

ZB-10

|

10

|

5-30

|

1

|

1.5

|

|

ZB-20

|

20

|

10-60

|

2

|

2.2

|

|

ZB-31.5

|

31.5

|

15-90

|

2

|

3

|

|

ZB-50

|

50

|

25-150

|

3

|

4

|

|

ZB-100

|

100

|

50-300

|

4

|

5.5

|

|

ZB-150

|

150

|

75-450

|

5

|

7.5

|

|

ZB-200

|

200

|

100-600

|

6

|

11

|

|

ZB-250

|

250

|

125-750

|

8

|

15

|

|

ZB-315

|

315

|

150-900

|

8

|

18.5

|

|

ZB-500

|

500

|

250-1500

|

12

|

22

|

|

ZB-800

|

800

|

400-2400

|

15

|

30

|

|

ZB-1200

|

1200

|

600-3600

|

20

|

37

|

|

ZB-2500

|

2500

|

1300-7500

|

24

|

45

|

|

ZB-3200

|

3200

|

1600-9600

|

24

|

55

|

|

ZB-6200

|

6200

|

3000-18000

|

30

|

75

|